The TongWELD tool is specially designed for laser welding of circular non-rotating joints of casing pipes of oil and gas wells in field conditions, with a diameter from 100mm up to 245 mm or more, in a vertical position.

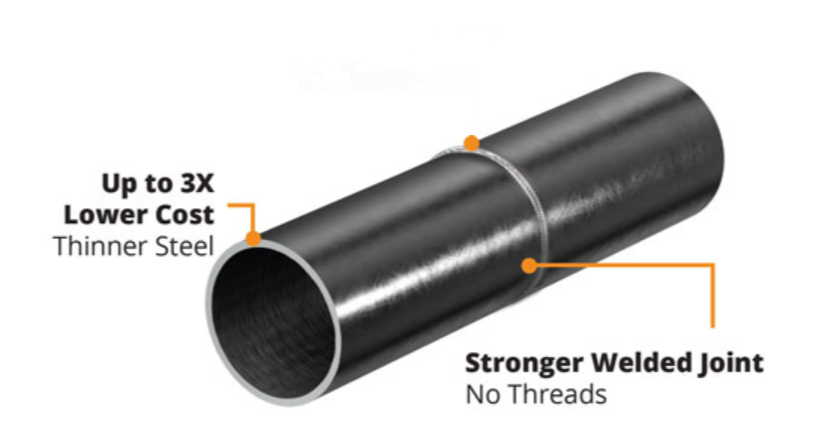

The system is equipped with lasers and heads manufactured by best laser company. The advantage of laser welding technology for casing pipes compared to traditional technology for mechanically joining casing pipes is a significant reduction in the cost of casing strings due to the elimination of conical threads and couplings, a reduction in the metal consumption of the casing string, as well as an increase in the ultimate strength and tightness of the casing string.

The system is equipped with lasers and heads manufactured by best laser company. The advantage of laser welding technology for casing pipes compared to traditional technology for mechanically joining casing pipes is a significant reduction in the cost of casing strings due to the elimination of conical threads and couplings, a reduction in the metal consumption of the casing string, as well as an increase in the ultimate strength and tightness of the casing string.

VALUE FOR INDUSTRY

Existing well construction

70% savings for threads

30% less metal consumption

High casing strength and improved casing integrity

Slim well design (no couplings)

20% total well cost reduction

Drilling with the casing

3 times higher torque for casing rotation

Left and right casing rotation

Easy run in hole - no couplings

70% savings for threads

30% less metal consumption

High casing strength and improved casing integrity

Slim well design (no couplings)

20% total well cost reduction

Drilling with the casing

3 times higher torque for casing rotation

Left and right casing rotation

Easy run in hole - no couplings

4 1/2 in casing laser welding

Laser Casing Welding video

9 5/8 in casing laser welding

Laser Casing Welding video

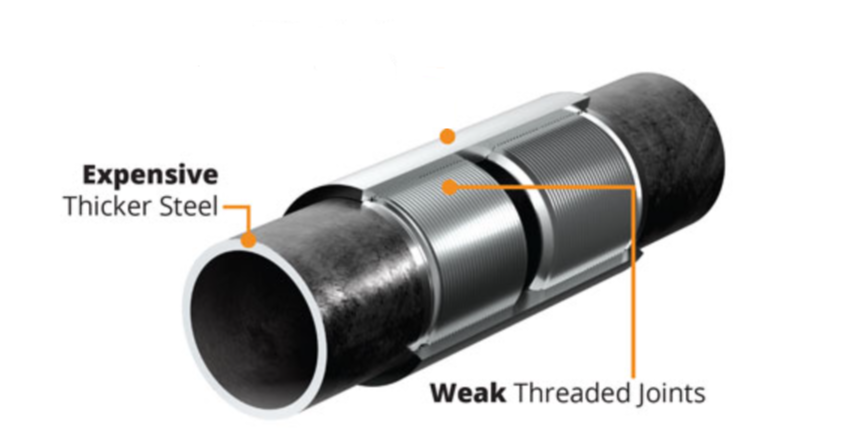

WELDED VS THREADECASD ING

WELDEDlower well construction costs - lim hole opportunities

WELDEDlower well construction costs - lim hole opportunities

maximum torque available for casing rotation

enhanced cement jobs with casing rotation

high strength & better casing integrity THREADEDhigher well construction cost

THREADEDhigher well construction cost

larger well diameter & volume drilling fluid & cement

less torque for casing rotation

poor cement jobs with out casing rotation

weaker casing strengthless casing integrity

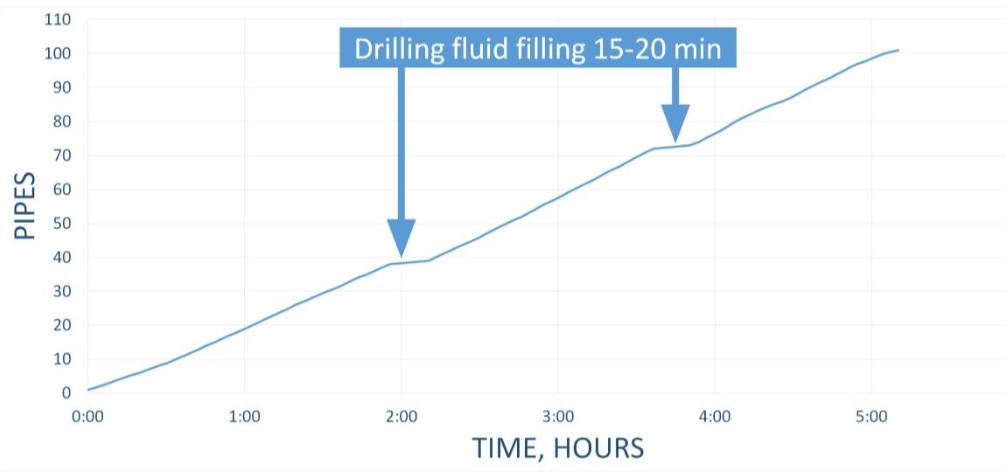

CASING RUNNING SPEED

Actual casing 4 1/2" casing runnig in hole time log

Running speed 5 hrs for 1000m of 4 1/2" casing

Running speed 5 hrs for 1000m of 4 1/2" casing

LABORATORY TESTS

TORQUE TEST114 x 6.5 mm Pipe

TORQUE TEST114 x 6.5 mm Pipe

23.4 kNm Force

NO WELD DAMAGE TENSILE STRESS TESTNO

TENSILE STRESS TESTNO

WELD

DAMAGE BENDING STRESS TESTNO CRACKS

BENDING STRESS TESTNO CRACKS

AT

WELD JOINT

114x6.3mm (41/2") casing | Welded joint | Threaded joint |

Casing Type | LOW COST A 516-55 Steel | High Cost N80 Steel |

Maximum Torque, kN*m | >34 | 13 |

Burst Pressure, bar | 770 | 623 |

Tensile load capacity of casing string, kN | >1600 | 1367 |

Need more information ?

Leave you contacts and we will contcat you